Innovative cleaning technology boosts cooling efficiency at UK

LEXINGTON, Ky. (April 23, 2025) — Energy efficiency is a high priority for University of Kentucky Facilities Management and has been for many years. This is evident in a 20% reduction in the amount of energy used per square foot since 2016. And recently, the process of cooling campus buildings just became more efficient.

Utilities and Energy Management, a unit in Facilities Management, installed new chiller tube cleaning technology on two chillers at the Central Utility Plant. This new technology will increase the resiliency of the campus’ cooling system and dramatically reduce the labor required to keep the chillers operating while saving thousands in electricity consumption.

“As part of our ongoing commitment to sustainability and energy efficiency, the installation of this technology represents the latest step toward optimizing energy use on campus,” said Mary Vosevich, vice president for facilities and chief facilities officer. “By streamlining maintenance processes with this technology, we’re not only saving valuable resources but also reinforcing UK’s role as a innovate leader in facilities management.”

UK uses district cooling, an energy-efficient process where chilled water is used to cool the majority of buildings on campus, including HealthCare facilities. Through this process, chilled water is produced at a network of central plants and distributed through miles of underground piping into buildings before returning to the plants. Chillers located in the cooling plants recool the returning water to make sure the cycled water is consistently sent to buildings at 42 degrees Fahrenheit.

During the process, scale and dirt enter the system and accumulate on the condenser tubes. The gradual accumulation of scale and dirt leads to a decrease in chiller energy efficiency over the course of the cooling season. The current cleaning process, which can only be done when the system is offline, requires an operator to send a brush through 1,000 tubes which are 35 feet long on each chiller. Cleaning one chiller can require 40 hours to complete.

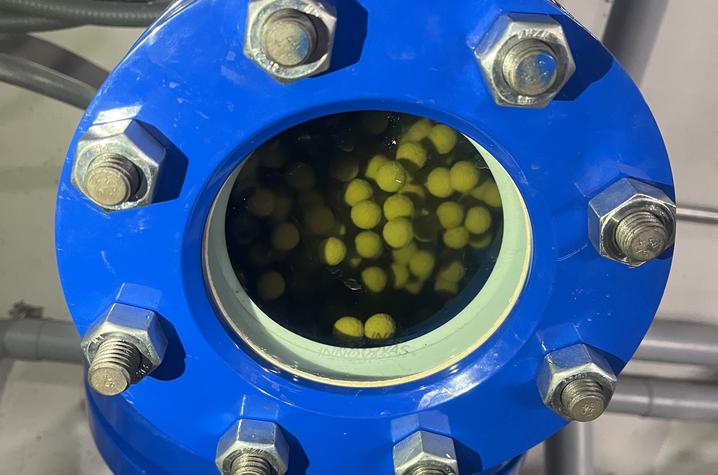

The innovative new cleaning system recently installed on two campus chillers operates by automatically injecting small rubber balls into the condenser water flow every 20 minutes. These balls scrub away scale and dirt without requiring manual labor or having the unit offline, significantly reducing the amount of time and effort involved in maintenance.

“Having a system that can keep the tubes clean year-round helps us fix the long-standing challenge of losing efficiency through the year as contaminants build up in the tubes,” said Carter Whitton, utilities systems manager in Facilities Management. “Achieving those improvements will be a tremendous energy saver and have a substantial sustainability impact.”

Adding the Helios Tube Cleaning System to two chillers will improve efficiency, saving tens of thousands of dollars a year. If the new system performs as expected, Utilities and Energy Management plans to expand the technology to their full fleet of chillers.

As the state’s flagship, land-grant institution, the University of Kentucky exists to advance the Commonwealth. We do that by preparing the next generation of leaders — placing students at the heart of everything we do — and transforming the lives of Kentuckians through education, research and creative work, service and health care. We pride ourselves on being a catalyst for breakthroughs and a force for healing, a place where ingenuity unfolds. It's all made possible by our people — visionaries, disruptors and pioneers — who make up 200 academic programs, a $476.5 million research and development enterprise and a world-class medical center, all on one campus.