Toyota Chairman Fujio Cho Visits UK Lean Systems Program

LEXINGTON, Ky. (Nov. 21, 2011) — The University of Kentucky Lean Systems Program welcomed back a very special friend to the program Thursday, Nov. 17.

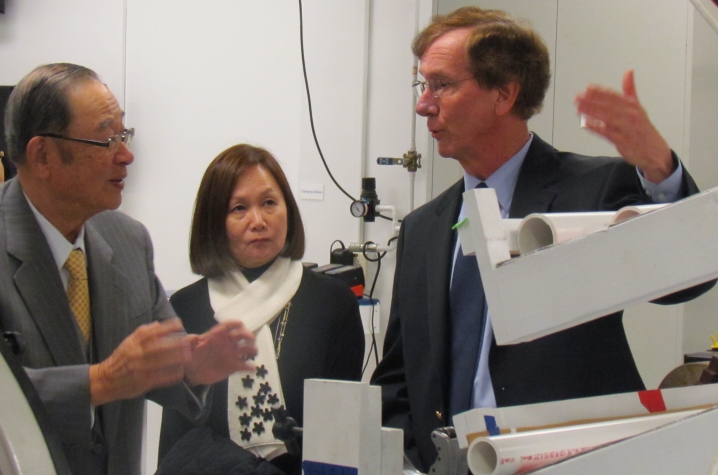

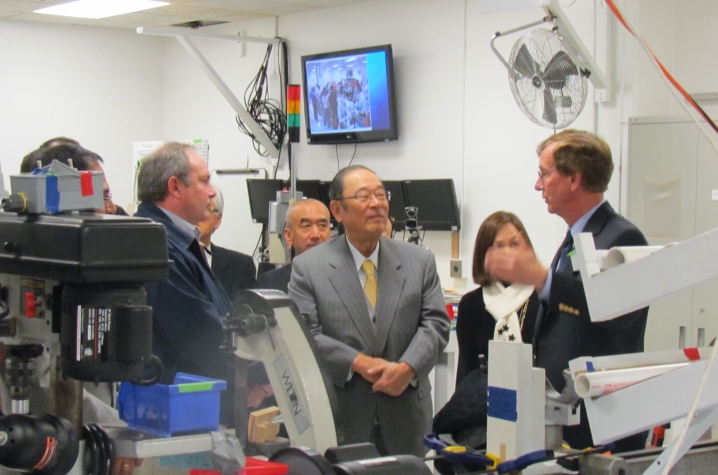

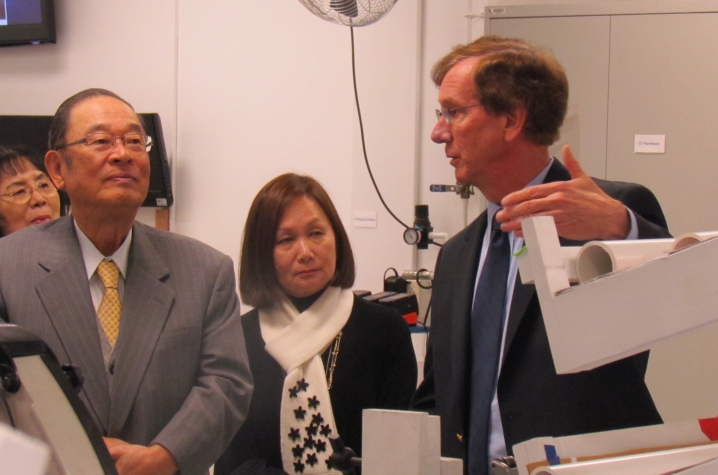

Fujio Cho, chairman of the Toyota Motor Corporation, visited the UK College of Engineering to meet with the Lean Systems group and tour the facility where the program conducts its trainings.

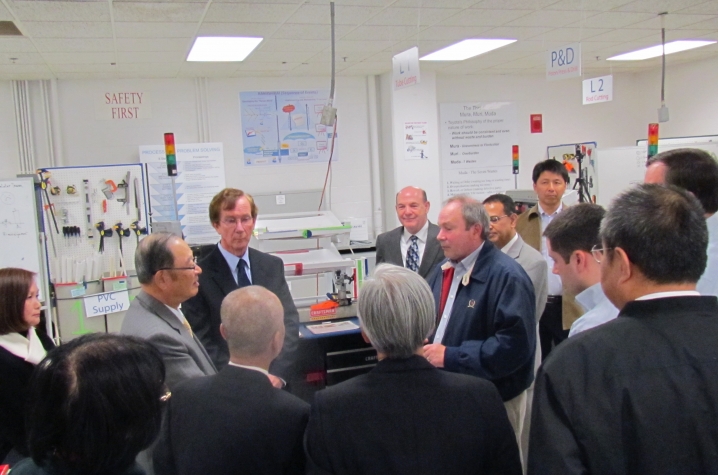

Toyota executive-in-residence Ken Kreafle, who serves as director of the Lean Systems Program, greeted Mr. and Mrs. Cho and their guests at a lean lab. Cho was also greeted by UK Provost Kumble Subbaswamy, College of Engineering Dean Thomas Lester, mechanical engineering Professor and Director of the Institute of Research for Technology Development (IR4TD) Kozo Saito, Toyota executive-in-residence Rich Alloo and other university officials. George Hofmeister, CEO of Revstone International, also joined the group greeting Cho. Most members of the Lean Systems Program were present.

While Cho has visited the university in the past (he received an honorary doctorate in 2002), last week's visit marked the first time he has visited the lean program. Saito normally makes annual trips to Japan with others from the program to meet with Cho and share what the UK lean program has accomplished.

"UK's lean program is very unique, and Cho indicated during our last visit to Japan that he was interested in visiting the program facilities," said Saito.

Cho, who was visiting Kentucky for the 25th anniversary of Toyota Motor Manufacturing, Kentucky (TMMK) plant in Georgetown, was invited to visit the program, which was designed from the beginning to expand the understanding of the Toyota Production System (TPS) to other non-Toyota companies.

[IMAGE6]His lab tour was conducted by Kreafle and Saito, along with lean instructors M. Abbot Maginnis, David Parsley, and Bill Cooper, who discussed the different stations in the lab and demonstrated how they conduct their trainings.

After visiting the lab, Cho sat down with the directors, the dean and the provost to discuss the program more in depth, and to encourage them to take their operation to the next level.

"We received a blessing from Cho for what we do, and he wants UK and Toyota to continue to work together in the future to bring us both up to this next level in lean systems training," Saito said.

"In our meeting, Cho continued to emphasize his respect for people, for the workers," Kreafle said. "As chairman of Toyota, he is still very interested in the person that builds the product, and wants TPS to bring a sense of satisfaction and respect to the worker for what they do."

For Kreafle, Cho's visit was also an opportunity to thank and acknowledge him as a mentor in his life and career. "Cho is truly a charismatic leader, and it was such an honor to have him visit this program and show his interest. He has had such a major impact on my career and has touched my life and thousands of others."

Saito agrees. "It's very good for UK and Toyota to work together to create these types of win-win scenarios to best serve the Commonwealth of Kentucky."

UK's lean program was developed as a university-industry partnership initiated by TMMK in 1994, and has since helped thousands of organizations around the world in increasing efficiency, cutting waste and improving leadership by teaching a nine-phase lean implementation sequence. Introduced in the early '90s, this "train the trainer" program has become known worldwide.

"TPS has evolved to lean manufacturing," said Kreafle. "Cho saw there was a need for this, and that's what we train our client companies to do. Not to copy TPS necessarily, but to develop their own management system based on their organization's principles. While the methods may be different, we're all still trying to get to the same destination, which is true lean."

MEDIA CONTACT: Jenny Wells; (859) 257-5343; Jenny.Wells@uky.edu